Bills of Materials (BOM)

A Bill of Materials (BOM) acts as a recipe for your products. It defines exactly which component items (ingredients) and quantities are required to build one unit of a finished good.

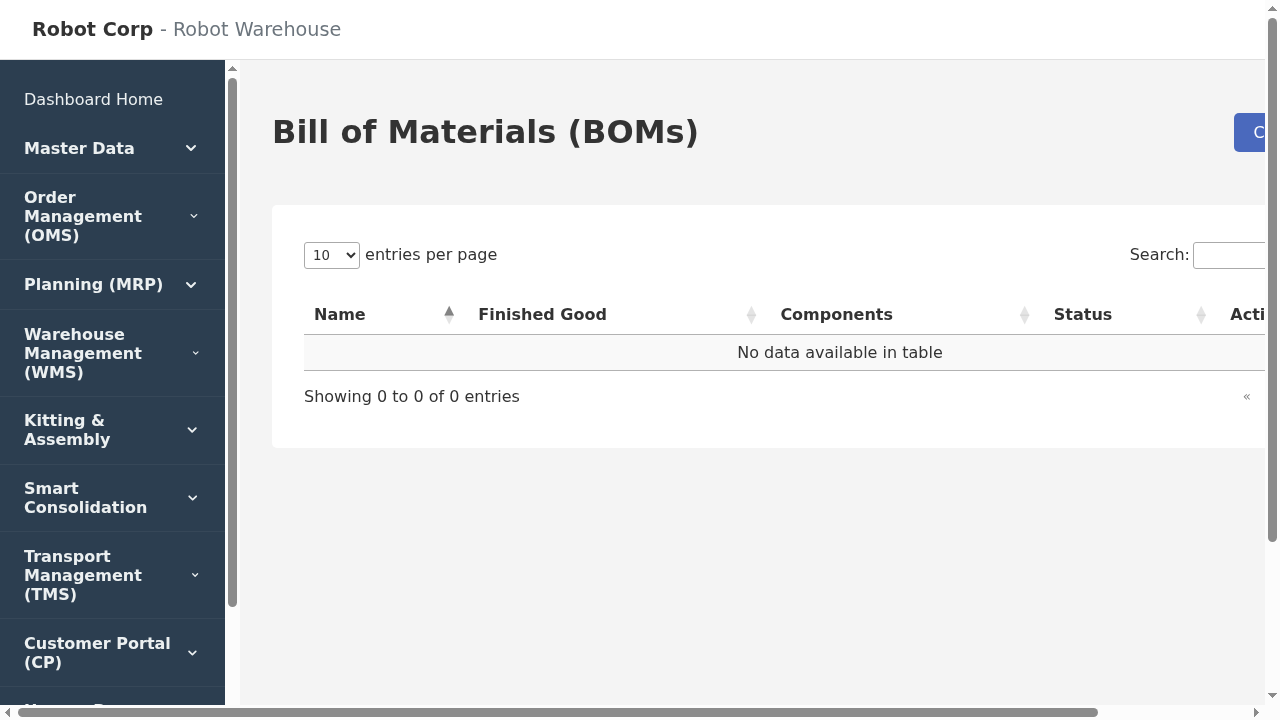

BOM Management Screen

Creating a BOM

- Finished Good: Select the product that will be produced. This product must exist in your Master Data.

- Components: Add the raw materials or sub-components required.

- Quantity: Define how many of each component are needed to make 1 unit of the finished good.

Note: A product can only have one active BOM at a time. This prevents ambiguity during the manufacturing process.

Usage

Once a BOM is active, it is used by:

- MRP Engine: To calculate raw material requirements based on demand for the finished good ("Exploding the BOM").

- Work Orders: To direct assembly staff on what to pick and build.